Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

Iron and Manganese are the most common metals we deal with as contaminants in the water treatment industry. Their presence can generate objectionable tastes, odors, staining, and coloring of anything they come into contact with. The methods for treating and removing them from water supplies have been around for hundreds of years. The process for removing them can be both easy and (WATER IS 50% SCIENCE AND 50% EXPERIENCE) difficult, depending on their concentration individually or together. Public water supplies don't typically deal with these constituents because they source their water from surface sources. Private water wells in the upper Midwest, Mid-Atlantic Northeast and the Pacific Northwest of the United States can almost guarantee they'll have one, if not both iron and manganese present at some level. Iron is the 4th most abundant element in the earth's crust and comprises around 5% of it, while manganese is around 0.1%. Iron and manganese bearing bedrock formations are dissolved into groundwater typically from the presence of free CO2. Iron concentrations in groundwater typically range from 0-10.0 mg/L, but 20 mg/L or higher are not uncommon. Manganese is much less common, and typically ranges from 0-2.0 mg/L.

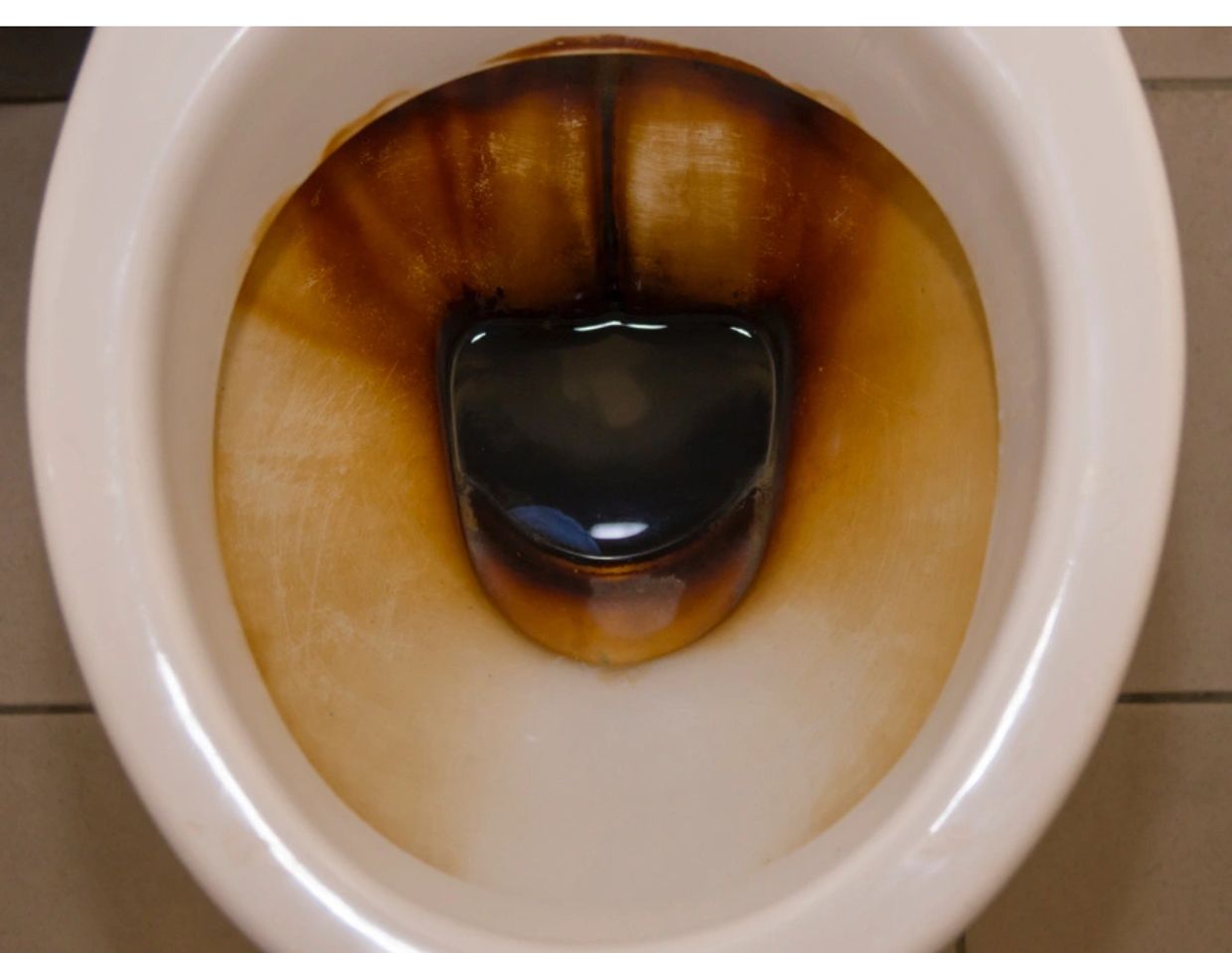

There are no health concerns related to either iron or manganese, except for at high concentrations. The EPA has set secondary drinking water standards for iron at 0.3 mg/L and 0.05 mg/L for manganese. At concentrations equal to or higher than these levels, they can cause aesthetic problems in homes and water systems. Iron and manganese are common in four different forms in water. The first is the ferrous state where water appears clear and the metals are dissolved in solution, often referred to as clear water iron or manganese. Groundwater systems are typically high in dissolved carbon dioxide with low or absent levels of dissolved oxygen resulting in clear water iron or manganese. Dissolved iron and manganese exist as bicarbonate salts, Fe(HCO3)2 and Mn(HCO3)4. The second is the ferric state where the metals have been oxidized and have precipitated out of solution, giving a reddish brown to black coloring of the water. After exposure to oxygen over time, the metals will react to form insoluble ferric states and cause discolored water or staining. The third form is the organic state, where the metals have been absorbed by bacteria or they are part of some organic complex. The fourth state is the colloidal form where the metals are bound up in organic substance like tannins or inorganic silica compounds. Determining what form the metal is in and the concentration will dictate the appropriate course of treatment. Most analyses measure iron as total iron and do not dictate between ferrous and ferric iron. A simple way to determine the concentration of ferric and ferrous iron is pass the water sample through a 10 micron (μm) filter paper and perform an iron analysis on the sample before and after the filter paper. The ferric (precipitated) iron will be trapped by the filter paper while the ferrous (dissolved) iron will pass through the filter paper.

Treating or removing iron and manganese from drinking water is dependent on a number of variables including pH, concentration, and the form that it exists in. The most common approach for iron and manganese removal is precipitation and filtration. Precipitation involves the use of some sort of oxidation process to push the iron and manganese from a ferrous or dissolved state to the ferric or precipitated state. Oxidation occurs when one atom transfers electrons in an oxidation-reduction reaction. The atom that loses electrons (reducing agent) is oxidized and the atom that gains the electrons (oxidizing agent) is reduced. Oxidizing agents include oxygen, ozone, and chlorine. During iron oxidation, ferrous bicarbonate Fe(HCO3)2 is oxidized to form ferric hydroxide Fe(OH)3. Both iron and manganese oxidation are heavily dependent on pH. Below a pH of 7, oxidation processes are very slow and require a long contact time for oxidation to occur. Iron oxidation occurs best within a pH range of 7.5-8.5, while manganese oxidation occurs best at a pH of 8.0 or higher. Generally speaking, a pH increase of 1 results in about a 100 fold increase in the rate of iron oxidation, so a higher pH results in more rapid oxidation.

Catalytic oxidation and filtration typically uses manganese oxide based catalytic medias such as Katalyst Light. A catalyst is a substance that changes the rate of a chemical reaction without being consumed or chemically changed by the chemical reaction. Catalytic medias require specific operating conditions and are heavily dependent on pH. When iron and manganese come into contact with Katalyst Light, they are quickly oxidized, precipitate out of solution, and are filtered out by the media bed. Katalyst Light filters need to be regenerated often, as they act as a catalyst between dissolved oxygen in the water and the target contaminants.

It is vastly easier to remove Iron from water than Manganese. Why?

Manganese is generally harder to oxidize and remove than iron due to several key factors related to their chemical properties and behaviors in reactions:

1. Electronegativity and Ionization Energy: Manganese has a higher electronegativity and ionization energy compared to iron. This means that manganese holds onto its electrons more tightly, making it less reactive in oxidation reactions.

2. Oxidation States: Manganese can exist in multiple oxidation states (from -3 to +7), with +2, +4, and +7 being the most common. This versatility allows manganese to stabilize in various forms, making it less prone to oxidation under certain conditions compared to iron, which primarily exists in +2 and +3 states.

3. Thermodynamic Stability: The thermodynamic stability of manganese oxides is generally higher than that of iron oxides. Manganese oxides tend to be more stable and require more energy to break down or reduce back to the metal form.

4. Reaction Kinetics: The kinetics of oxidation reactions differ for manganese and iron. Manganese often requires stronger oxidizing agents or harsher conditions for oxidation compared to iron, which can oxidize more readily in the presence of oxygen and moisture.

5. Passivation: Iron can form a passive layer of iron oxide that can protect it from further oxidation, while manganese does not form such a protective layer as readily, leading to different behaviors in oxidation processes.

These factors contribute to the overall difficulty in oxidizing and removing manganese compared to iron in various chemical contexts.

System is made for impossible to remove problematic Manganese. Manganese oxidizes much slower than iron. A pH of around seven or below seven can make manganese removal a very difficult task. The guardian well has three different medias to raise the pH to about 8.5 to 9.0. This elevated pH makes removing manganese and iron, fairly easy and quickly.

1.0 cu/ft. = 6-8 gpm

1.5 cu/ft. = 10-12 gpm

2.0 cu/ft.= 12-16 gpm

2.5 cu/ft. = 16- 24gpm

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.