Products from our Reaseach and Development Lab

AQUASORB a breakthrough in material science. Innovative adsorption technology.

AQUASORB represents the pinnacle of innovation in water management and Adsorption technology. This cutting-edge product is designed to effectively capture, retain, and purify water, making it an indispensable solution for water pollution.

Broad Spectrom removal capabilities

O

Regeneration restores capacity

UNBELIEVABLY EFFECTIVE WATER PURIFICATION TECHNOLOGY

A NEW ERA IN WATER PURIFICTION. PUREREDOX

INTRODUCTION

PureRedox is the world’s first High-Redox Technology, a next-generation granular filtration media that revolutionizes water treatment by Advanced Oxidation Reduction

(Redox) processes.

PureRedox is uniquely engineered using two specialized carbon-based adsorbers: Zn

Zn-Mesoporous Metal Organic

Framework incorporated with Copper

ions on Modified Activated Carbon.

70% Copper-Coated Activated Carbon (Cathode) 30% Zinc-Coated Activated Carbon (Anode)

HOW PureRedox WORKS

THE REDOX MECHANISM

PureRedox is a dual-function granular filtration media that integrates:

Zinc-Coated Activated Carbon as an Anode

(Electron Donor)Copper-Coated Activated Carbon as a Cathode (Electron Acceptor)

Together, these two highly conductive, regenerable carbons create an electrochemical Redox reaction that

eliminates at an atomic level. This self-sustaining redox cycle ensures superior oxidation, disinfection, and organics

removal, including heavy metals, setting a new standard in water treatment efficiency.

As water flows through the PureRedox filtration media, it undergoes a continuous electro chemical reaction, where

the zinc-coated carbon donates electrons (Oxidation) and the copper-coated carbon accepts electrons (Reduction).

This controlled redox environment destroys organic contaminants, reduces heavy metals, and neutralizes

harmful microorganisms.

WORLD’S FIRST HIGH-REDOX T E C H N O L O G Y

This reaction produces highly active Hydroxyl Radicals

(OH•), Sulfate Radicals (SO4• ), Superoxide Radicals (O2• )

Making PureRedox one of the most powerful non-toxic oxidizers available.

ELIMINATES 99.9% OF

KILLS BACTERIA & VIRUSES

Glyphosate, Heptachlor/Heptachlor Epoxide, Hexachloro

benzene, Methoxy chlor, Methylene chloride, Pentachloro-

phenol, Polychlorinated Biphenyls (PCBs), Pyrethroids,

Toxaphene.

All these contaminants have serious health effects.

Biofilm, Legionella, E. Coli, Salmonella, Pseudomonas

NEUTRALIZES ALL DISINFECTION BYPRODUCTS

ELIMINATES PHARMACEUTICALS

No Chlorine, No Halogenated by products (HBPs) These are

very toxic. No Trihalomethanes (THMs: mainly Chloroform)

and No Haloacetic Acids (HAAs), with Smaller amounts of

Haloaldehydes, Haloacetonitriles and Haloketones.

KEY FEATURES & ADVANTAGES

KEY FEATURES & ADVANTAGES

Granular High-Resolution Redox Media

Dual-Coated Carbon Design : 70% Copper-Coated

Activated Carbon (Cathode) + 30% Zinc-Coated Activated Carbon (Anode)

Self-Sustaining Redox Cycle: No external power source required

Regenerable & Long-Lasting: Unlike traditional media,

PureRedox can be recharged for continuous use Electrochemical Advanced Oxidation Process (EAOP)

Generates Hydroxyl Radicals (OH•) and Sulfate Radicals

(SO4• ) for unparalleled contaminant breakdown.

Provides a continuous source of oxidation without degrading over time.

Sustainable & Non-Toxic

No Chlorine, Sodium Hypochlorite, Calcium Hypochlo-

rite, Chlorine Dioxide and Chloramines including HOCl.

Adsorbs THMs & DBPs

Removes contaminants without adding harmful chemi-

cals to water.

Fully biodegradable & environmentally friendly

Multi-Contaminant Removal Efficiency

Removes more troublesome Pollutants than any other filtration media

Technology Type

High-Resolution Redox-Media

Base Material

High-Class Activated Coconut Carbon

Coating

Composition

MOFs (Metal-Organic Frameworks)

70% Copper-Coating + 30% Zinc-Coating

Appearance

Granular, Dark Grey/Black

Regeneration

Fully regenerable

Non-Toxic, Environmentally Safe

CHEMICAL & PHYSICAL PROPERTIES

Parameter

Value

Oxidation-Reduction Potential (ORP)

+900 to +950 mV

pH Stability Range

6.0 – 9.5

Sulfate Radical Generation

YES

Hydroxyl Radical Formation

YES

Reaction Speed

Very Fast

Chemical-Free

YES

Power-Free

YES

Maintenance-Free

YES

Cost Effective

YES

Bacteria & Viruses

99.9%

Biofilm Removal

99.9%

Pesticides & Herbicides

99.9%

Pharmaceuticals & PPCPs

99%

Lead

99.9%

Mercury

99.9%

REGENERABLE, SAFE,

AND CHEMICAL-FREE DISINFECTION

FOR A HEALTHIER ENVIRONMENT.

Best available technology

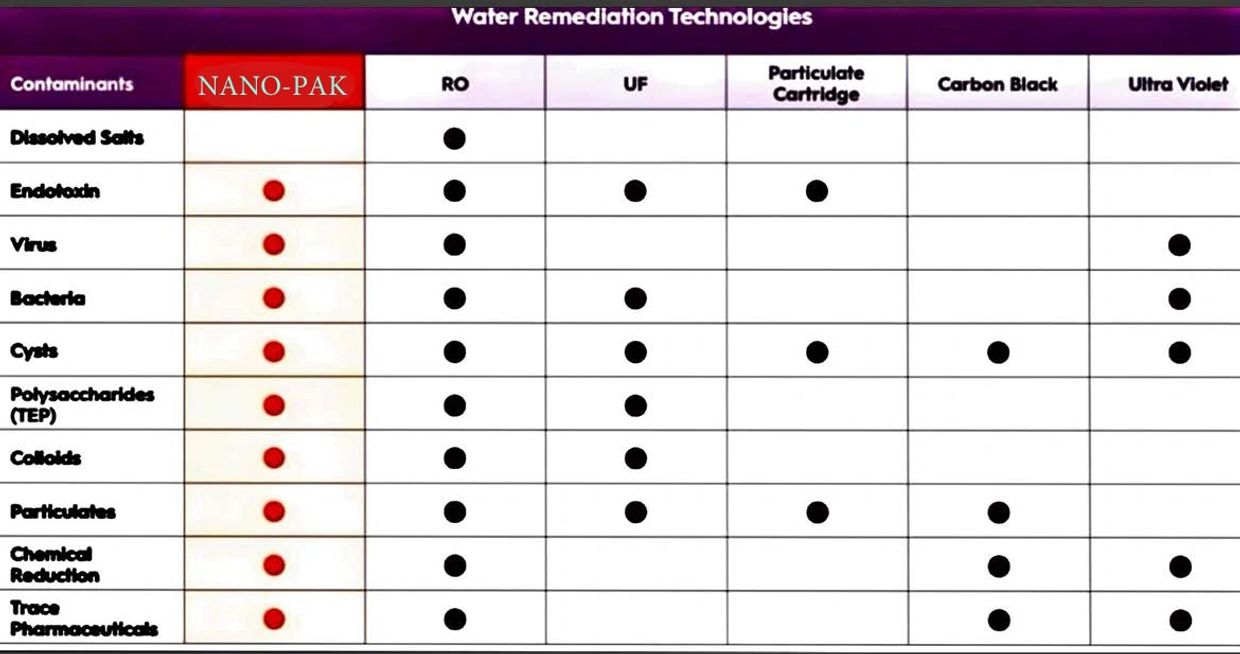

NEXT GENERATION NANO TECHNOLOGY. ELECTRO POSITIVE TECHNOLOGY. THE NANOPAK FILTER HAS UNIQUE FEATURES

The Amazing NANO-PAC

A MUST HAVE FOR MOST WATER FILTER TREATMENT TREES .

NanoPak

Electro-adsorptive technology

Nano-Pak is an electro-adsorptive technology. It uses an electrical charge to remove very small pathogens, like E.coli and Legionella, from the water, while ensuring the healthy minerals that are good for us remain.” This single-source approach to purification is also the most sustainable.

Removes bacteria at more than 99.9999%, including E. coli

Independent testing has shown filter media to reduce MS2 virus at more than 99.99%. It can reduce a wide range of bacteria at more than 99.9999%, including E. coli, Pseudomonas and Legionella.

Removal of pharmaceuticals

Pharmaceutical removal studies

Dirt holding capacity

How the NanoPak compares to membrane filtration

520 UF

3 Stage Purification Point Of Use Filter Ultrafilter membrane,carbon block and scale treatment

'

Problem water specialists

Aquametrics is not a marketing company, we have been in a 1000 well water pumphouses.

Aquametrics has found, not only does the correct treatment technique need to be deployed, but creating the optimum environment for that treatment technique to perform is critical to long problem free success.

A patent pending hardness and scale electronic device

THE TURBO DESCALER

A BETTER ALTERNATIVE to water softeners. The descaler represents modern innovation that can Treat the scale hardness in your water and on your pipes. The Descaler mitigates the damaging effects of hard water without adding any salt to the the environment.

A few of our water treatment medias

SURFACE ENHANCED WITH ZERO VALENT IRON

INDUSTRY LEADER IN SALTLESS WATER CONDITIONING

INDUSTRY LEADER IN SALTLESS WATER CONDITIONING

CATALYTIC CARBON® is Coconut carbon CATALYTIC CARBON® is tested to meet NSF 61 Standard

CATALYTIC CARBON® is Catalyzed with Iron (“Catalytic Structure”)

Iron Catalyst has the highest Oxidation and Adsorption pores “Inside as well as Outside the Activated Carbon”

Surface of CATALYTIC CARBON® ranging from 2000 m2/g to 2500 m2/g

Iron Particles coated inside and outside the micro-pores of CATALYTIC CARBON® eliminates the need of expensive Ion- Exchange and Membrane Process.

Catalytic-Carbon™ Removal methods:

1. Mechanical Filtration (fine particles, TSS, Turbidity down to 1 micron)

2. Adsorption of organic contaminants

3. Adsorbtion of inorganic contaminants (e.g. As, Heavy Metals, Radionuclides)

INDUSTRY LEADER IN SALTLESS WATER CONDITIONING

INDUSTRY LEADER IN SALTLESS WATER CONDITIONING

INDUSTRY LEADER IN SALTLESS WATER CONDITIONING

Introduction

The combination of FILTERSORB® SP3 and FILTERSORB SPA is an excellent choice for all residential, industrial, and commercial applications since it provides optimum scale prevention. The FILTERSORB® CT as a combined technology results in very high efficiency and provides additional capacity to the system.

The FILTERSORB® SP3 and FILTERSORB® SPA combination is well suited to treat water with hardness over 15 grains or permanent hardness over 250 mg of (Ca + Mg + SiO2 + SO4) is typically over 60 % of the total anions.

LEARN MORE ABOUT THIS ADVANCED TECHNOLOGY

Premiere iron and manganese filter media

INDUSTRY LEADER IN SALTLESS WATER CONDITIONING

It took 10 years to manufacture the catalyst and to develop

Katalyst Light, formally known as Katalox Light.

Katalyst light is a manganese dioxide based Catalyst media that can split water efficiently into Hydrogen (H*) and Hydroxide (OH-) at pH

from 5.6 to 10.5

. Hydroxide ions are used for the precipitation of heavy metals up to 99.99%. Which represents the highest percentage of metal removal than any media in water treatment.

Proprietary Catalvst turns cations into stable insoluble or solid-state particles and then removes them with backwash.

The process cannot be compared with other technologies. Other flocculants like Pyrolox, Filox or Greensand Plus are antiquated.

Proprietary Catalvst turns cations into stable insoluble or solid-state particles and then remove any with backwash.

At Aquametrics we use natural processes, not chemicals.

Application

- To Filter out suspended solids.

- Due to its high alkalinity, it is easy to control the pH without using any chemicals.

- Remove silica effectively compared to Ion exchange Resin’s and Membranes.

- Remove Phosphorus effectively compared to any other technology available in the Market.

- Remove CO2 and H2S including Ammoniain the water or wastewater

- Controlling Corrosion of the Municipal and Utilities network without adding any Corrosion inhibitors

- The simplest process of enriching water with Mg2+ ions to be salinated and softened water

- Solve all scaling problem’s in wastewater tanks with its long-lasting alkalinity/pH control. Easy and safe to handle since.

- NON-HAZARDOUS

- NON-CORROSIVE

- NON-TOXIC

Best particulate filtration media on the market

.

CRYSTOLITE can be used to filter down 0.5 microns without clogging.

It allows all suspended solids to accumulate on the surface of the CRYSTOLITE and are easily backwashed to drain.

The backwash cycle is 3 minutes to a maximum of 10 minutes.

CRYSTOLITE uses 80% less water than any traditional anthracite or multimedia filters, it is because 90% of the solids are captured on the surface and not inside of the CRYSTOLITE.

High-tech filtration that can filter solids and particles down to submicron levels

at 10 to 15

times the flow rate of all traditional filters.

Raises PH and removes heavy metals.

High Capacity Adsorber plus De-Adsorber to selectively Trapp Nitrates

World’s first High Capacity Adsorber plus De-adsorber to selectively Trapp Nitrates. It has 5 times higher capacity than any other commercially available adsorber in the market. Nitrotrapp is certified and has been specially manufactured to meet Drinking Water standards and has passed,

Taste and Odor tests

100% De-adsorption test

Nitrotrapp is different from all other nitrate removal systems in the market in several aspects. The custom designed adsorber removes not only nitrates from drinking water, but also provides healthy bicarbonates. “This can’t be achieved simply by any other media, which are based on Ion Exchange or Reverse Osmosis.” Anion exchange for nitrate removal is similar to a water softener, where relatively large amount of sodium chloride are typically used.

CHEMICAL FREE PH DOWN MEDIA. PH DOWN WITHOUT ACID INJECTION.

The adsorption of Anions increases with decreasing pH

The removal of contaminants have many variables when deciding which treatment technique to deploy.

Optimum PH for fluoride removal:

Inorganic Coagulant: Optimum pH for fluoride removal was 6.5.

General Removal: For general fluoride removal, the water pH should be between 5.0 and 6.3.

Optimum PH for Arsenic removal:

General Removal: For general Arsenic and Fluoride removal, the water pH should be between 6.0 and 6.5.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.