Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

We are a leading provider of water treatment equipment, offering a range of products designed to meet the needs of residential, commercial, and industrial customers. Our team of experts has years of experience in the industry and is committed to delivering top-quality solutions that are both effective and affordable.

We offer a wide range of water treatment solutions to meet the needs of any customer. From residential to commercial to industrial applications, we have the expertise and resources to deliver top-quality solutions that are both effective and affordable. Off the shelf and customized water treatment solutions.

Legal does not equal safe. You need to take your water quality into your own hands. Buy a filter or be a filter.

AQUASORB represents the pinnacle of innovation in water management and Adsorption technology. This cutting-edge product is designed to effectively capture, retain, and purify water, making it an indispensable solution for water pollution.

O

INTRODUCTION

PureRedox is the world’s first High-Redox Technology, a next-generation granular filtration media that revolutionizes water treatment by Advanced Oxidation Reduction

(Redox) processes.

PureRedox is uniquely engineered using two specialized carbon-based adsorbers:

HOW PureRedox WORKS

THE REDOX MECHANISM

PureRedox is a dual-function granular filtration media that integrates:

Zinc-Coated Activated Carbon as an Anode

(Electron Donor)Copper-Coated Activated Carbon as a Cathode (Electron Acceptor)

Together, these two highly conductive, regenerable carbons create an electrochemical Redox reaction that

eliminates at an atomic level. This self-sustaining redox cycle ensures superior oxidation, disinfection, and organics

removal, including heavy metals, setting a new standard in water treatment efficiency.

As water flows through the PureRedox filtration media, it undergoes a continuous electro chemical reaction, where

the zinc-coated carbon donates electrons (Oxidation) and the copper-coated carbon accepts electrons (Reduction).

This controlled redox environment destroys organic contaminants, reduces heavy metals, and neutralizes

harmful microorganisms.

Glyphosate, Heptachlor/Heptachlor Epoxide, Hexachloro

benzene, Methoxy chlor, Methylene chloride, Pentachloro-

phenol, Polychlorinated Biphenyls (PCBs), Pyrethroids,

Toxaphene.

All these contaminants have serious health effects.

Biofilm, Legionella, E. Coli, Salmonella, Pseudomonas

NEUTRALIZES ALL DISINFECTION BYPRODUCTS

ELIMINATES PHARMACEUTICALS.

Advanced Chloramine Filters

Aquametrics has the best Chloramines removal technology in the industry.

All Aquametrics adsorbers can be regenerated to restore their capacity.

The relationship between carbon surface area, contact time, and the removal of chloramines from water is crucial for effective water treatment.

Most coconut shell carbons are 85% micropore slot size.Chloramines are a large Macro-pore compound.

Aquasorb’s unique pore structure consisting of Positive as well as Negative micro-pores, meso-pores, and macro-pores. Aquasorb adsorber has 90% Macro-Pores making it absolutely unique with a surface area of about 6000-6500 m²/g

A couple of key considerations need to be considered when selecting Chloramine water treatment:

Filter Media. Surface Area

Aquametrics ZVI. 2800 m² per gram

Aquametrics AquaSorb. 6500 m² per gram

Aquametrics PureRedox 1800 m² per gram

Calgon Centaur 950 m² per gram

Jacobi Petrosorb 1050 m² per gram

Surface area

A larger carbon surface area improves chloramine removal efficiency.

Chloramine is a much more stable molecule than chlorine. Its removal is not a rapid reaction but a slower catalytic decomposition process on the carbon's surface, often requiring a longer duration for the bond between the chlorine and ammonia to break down. This process converts the chloramine into harmless products like nitrogen gas and chloride ions.

If the decomposition is not completely finished Carbon can have its capacity lowered to 1/8th of the capacity it has for chlorine.

Contact time:

Longer contact times are beneficial for effective adsorption.

Flow rate:

The interplay between flow rates and contact time is critical for optimizing treatment systems.

If you're looking for specific figures or studies on this topic, I can help with that as well!

The relationship between carbon surface area, contact time, and the removal of chloramines from water is crucial for effective water treatment.

1. Carbon Surface Area

Activated Carbon: The effectiveness of activated carbon in removing chloramines largely depends on its surface area. A larger surface area provides more sites for adsorption, which enhances the removal efficiency.

2. Contact Time

Importance of Contact Time: Contact time refers to the duration that water is in contact with the carbon filter. Longer contact times generally allow for more chloramines to adsorb onto the carbon surface.

Flow Rates: Higher flow rates decrease contact time, which can limit the effectiveness of chloramine removal. Slower flow rates increase contact time, improvir d removal efficiency.

3. Adsorption Mechanism

Physical Adsorption: Chloramines are primarily removed through physical adsorption, where they adhere to the surface of the activated carbon.

Chemical Reaction: In some cases, chloramines can react chemically with the carbon, especially if the carbon has been treated with certain functional groups, such as Catalytic Carbon.

Optimal Conditions

Balance Between Surface Area and Contact Time: For effective chloramine removal, it's essential to balance surface area and contact time. High surface area carbon can be effective even with shorter contact times, while lower surface area carbon requires longer contact for effective removal.

System Design: Treatment systems should be designed to maximize both surface area and contact time, possibly through the use of multiple stages of filtration or varying carbon types.

Electro-adsorptive technology

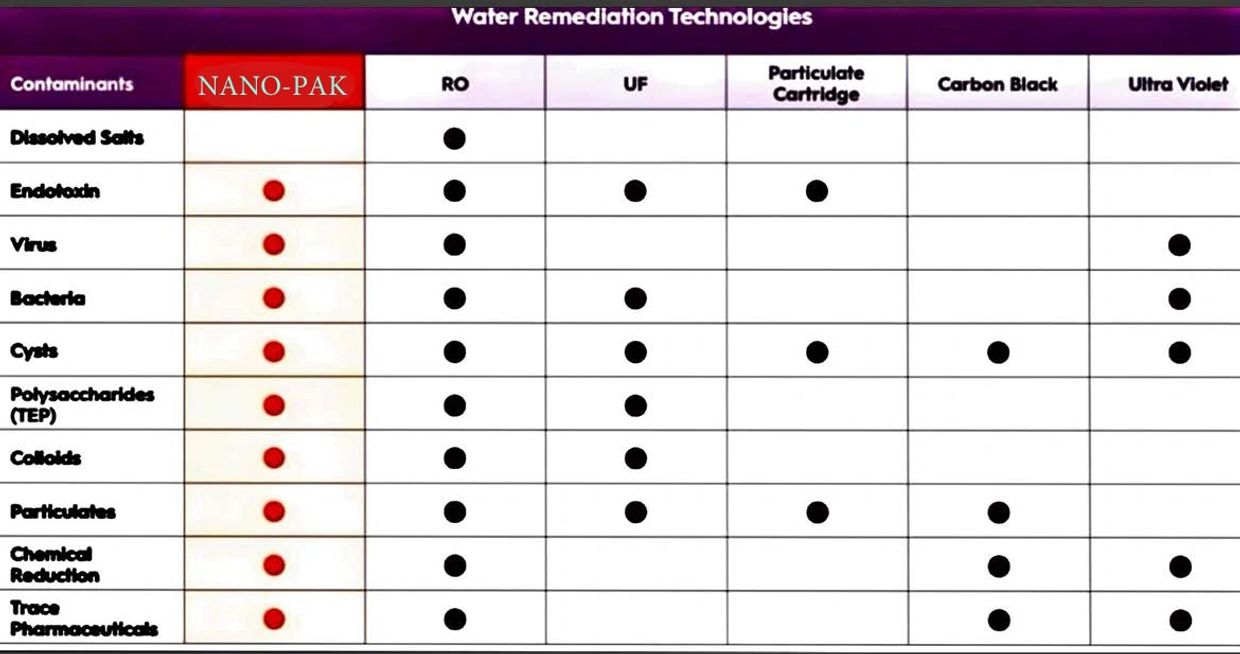

Nano-Pak is an electro-adsorptive technology. It uses an electrical charge to remove very small pathogens, like E.coli and Legionella, from the water, while ensuring the healthy minerals that are good for us remain.” This single-source approach to purification is also the most sustainable.

Independent testing has shown filter media to reduce MS2 virus at more than 99.99%. It can reduce a wide range of bacteria at more than 99.9999%, including E. coli, Pseudomonas and Legionella.

'

Aquametrics has found, not only does the correct treatment technique need to be deployed, but creating the optimum environment for that treatment technique to perform is critical to long problem free success.

A BETTER ALTERNATIVE to water softeners. The descaler represents modern innovation that can Treat the scale hardness in your water and on your pipes. The Descaler mitigates the damaging effects of hard water without adding any salt to the the environment.

CATALYTIC CARBON® is Coconut carbon CATALYTIC CARBON® is tested to meet NSF 61 Standard

CATALYTIC CARBON® is Catalyzed with Iron (“Catalytic Structure”)

Iron Catalyst has the highest Oxidation and Adsorption pores “Inside as well as Outside the Activated Carbon”

Surface of CATALYTIC CARBON® ranging from 2000 m2/g to 2500 m2/g

Iron Particles coated inside and outside the micro-pores of CATALYTIC CARBON® eliminates the need of expensive Ion- Exchange and Membrane Process.

Catalytic-Carbon™ Removal methods:

1. Mechanical Filtration (fine particles, TSS, Turbidity down to 1 micron)

2. Adsorption of organic contaminants

3. Adsorbtion of inorganic contaminants (e.g. As, Heavy Metals, Radionuclides)

The combination of FILTERSORB® SP3 and FILTERSORB SPA is an excellent choice for all residential, industrial, and commercial applications since it provides optimum scale prevention. The FILTERSORB® CT as a combined technology results in very high efficiency and provides additional capacity to the system.

The FILTERSORB® SP3 and FILTERSORB® SPA combination is well suited to treat water with hardness over 15 grains or permanent hardness over 250 mg of (Ca + Mg + SiO2 + SO4) is typically over 60 % of the total anions.

LEARN MORE ABOUT THIS ADVANCED TECHNOLOGY

.

World’s first High Capacity Adsorber plus De-adsorber to selectively Trapp Nitrates. It has 5 times higher capacity than any other commercially available adsorber in the market. Nitrotrapp is certified and has been specially manufactured to meet Drinking Water standards and has passed,

Taste and Odor tests

100% De-adsorption test

Nitrotrapp is different from all other nitrate removal systems in the market in several aspects. The custom designed adsorber removes not only nitrates from drinking water, but also provides healthy bicarbonates. “This can’t be achieved simply by any other media, which are based on Ion Exchange or Reverse Osmosis.” Anion exchange for nitrate removal is similar to a water softener, where relatively large amount of sodium chloride are typically used.

Optimum PH for fluoride removal:

Inorganic Coagulant: Optimum pH for fluoride removal was 6.5.

General Removal: For general fluoride removal, the water pH should be between 5.0 and 6.3.

Optimum PH for Arsenic removal:

General Removal: For general Arsenic and Fluoride removal, the water pH should be between 6.0 and 6.5.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.